Medication Safety

Overview

The perioperative area is often where you can find more high-alert medications, administered more per patient than any other care area of the hospital. Often referred to as a “black hole”, anesthesia providers often select, prepare, label and administer medications without technologies that help to remove human error, such as barcode scanning.

There are many opportunities for errors to be made. Some occur at the time of selecting the correct drug vial or ampoule related to incorrect concentration, failure to differentiate look-alike, sound-alike drugs and difficulty in reading drug manufacturer’s parenteral vial/ampoule labeling. Additional errors occur during medication preparation where the drug prepared and the identification of the contents is incorrect and/or illegible. Furthermore, errors have been documented at the time of administration where the anesthetist selects and administers the wrong syringe or an expired syringe. Vial/ampoule swaps, mislabeling and illegible labeling, and syringe swaps are the ORs three most common medication errors, accounting for >60% of the errors made in this environment.

“The error of one moment becomes the sorrow of whole life”

– A Chinese proverb

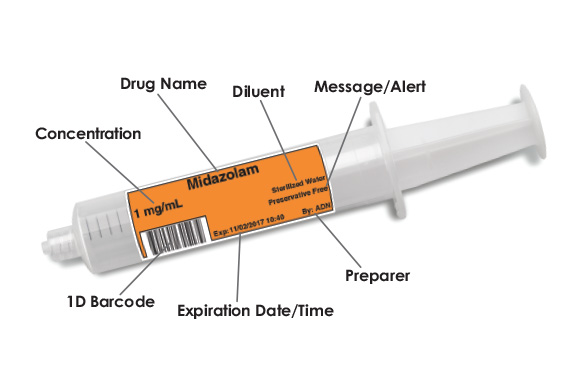

Complications from unlabeled or mislabeled syringes has in part prompted the Joint Commission on Accreditation of Healthcare Organizations to create National Patient Safety Goal 03.04.01: “Label all medications, medication containers (for example, syringes, medicine cups, basins), or other solutions on and off the sterile field.” In 2010, the APSF proposed a paradigm to reduce medication errors causing harm to patients in the surgical suite – STPC: standardization, technology, pharmacy/prefilled/premixed and culture. Specifically, in their technology review, APSF recommended all facilities:

- Employ a barcode scanning system to identify medications before preparing and/or administering them (Eichhorn, 2010)

- Provide a standardized, machine-readable barcoded label on all drug containers and/or syringes dispensed to the perioperative setting, or employ a similar just-in-time labeling system that can be used in the surgical setting (Eichhorn, 2010)

- Employ an electronic mechanism to provide feedback, decision support, and documentation of important data during the perioperative encounter (Eichhorn, 2010)

- Provide large and loud visual and auditory stimuli targeting multiple senses to verify drugs and concentrations, and to communicate important alerts.

The standard of care in the world’s leading ORs — Codonics Safe Label System

Safe Label System technology answers the call of the NPSG and APSF. Safe Label System safeguards the patient against the most common OR medication errors associated with medication preparation and administration and, in doing so, has a profound affect for the patient. SLS provides consistency at medication preparation complete with on-demand TJC-complaint labels that enable a double- and triple-check at the point of care achieving an unparalleled improvement to healthcare quality.

- SLS is the first and only system to provide an electronic “double-check” at preparation and a pre-administration “triple-check” that verifies the drug and concentration in hand as well as audibly and visually display the expiration status while ensuring TJC and USP requirements for added patient safety.

- SLS prepared compliant labels (that include a unique 2D barcode) provide verification of the drug to be administered to prevent syringe swaps.

- Codonics SLS-WAVE, a hands-free scanner, reads SLS prepared syringes (or any prefilled syringe with a barcode) enabling not only verification of the drug in hand but also documentation in the Anesthesiology Information Management System (AIMS) and electronic health records (EHR) as proof of administration and tracking of medication use.

- The SLS Administration Tool, a software application utilized in pharmacy, makes it practical and easy for pharmacy to control and manage the distribution of drugs, drug use rules and drug information to anywhere SLS resides throughout the hospital network (literally hundreds of locations with a single click of a button).

- In a truly first-of-a-kind approach, SLS’s innovative design improves medication preparation, consistency, and safety by consolidating use rules that include approved standard and non-standard concentrations, dilutions (dilution allowed, dilution not allowed, approved diluents) and total dose/total volume configurations to be available on demand at the point of care and carried through to compliant medication labeling that includes a 2D barcode (the very means to ensuring correct medication, preparation, expiration dates, administration and records — bringing BCMA to the OR) . No other system provides this comprehensive approach to remove human error and ensure compliance to best practice standards.